Vi tror på kraften hos digitala verktyg som ger företag möjligheten att mäta, analysera och optimera sina produktionsprocesser. Vårt mål är att hjälpa industrier att effektivt fördela resurser för ökad produktivitet och minimerad förlust. Med förståelsen för dessa nyckeltal i dagens konkurrensutsatta landskap är vi stolta över att introducera ett omfattande stöd för TAK/OEE (Overall Equipment Effectiveness) inom LE.MES plattformen, ett stöd som vi utvecklad i nära samarbete med våra kunder.

OEE, which stands for Overall Equipment Effectiveness, is a crucial metric used in manufacturing and production to assess and enhance the efficiency of equipment and processes. It is a measure that evaluates how effectively equipment is utilized in terms of availability, performance, and quality, providing insights into the overall productivity of a manufacturing operation.

The three key factors for OEE are:

Availability: This component measures the percentage of time that equipment or process is available and ready for production.

Performance: It evaluates the speed at which the equipment or process operates compared to its maximum designed speed.

Quality: This factor assesses the percentage of good products manufactured by the equipment or process, taking into account any products that do not meet quality standards or require rework.

OEE serves as a powerful tool for identifying inefficiencies, setting improvement targets, and implementing strategies to optimize equipment and processes within manufacturing environments. It helps organizations track progress, reduce waste, and increase output without necessarily acquiring additional resources.

Implementation av Overall Equipment Effectiveness

Scheduled time

Scheduled time for equipment and processes are described in Planning module..

Availability, performance and Quality

Operations and stops are managed in the Production-modulePerformance can be measured by allowing operators to manually initiate and conclude operations, register stops, and record produced and scrapped units.

Alternatively, the Device Communication module and Data Collector module enable automated equipment or processes to communicate all or some of this information.

The Recipes & instructions module are used to evaluate planned pace as a function of the equipment or process and all possible characteristics known regarding the operation, e.g. the article produced.

Analys av Overall Equipment Effectiveness

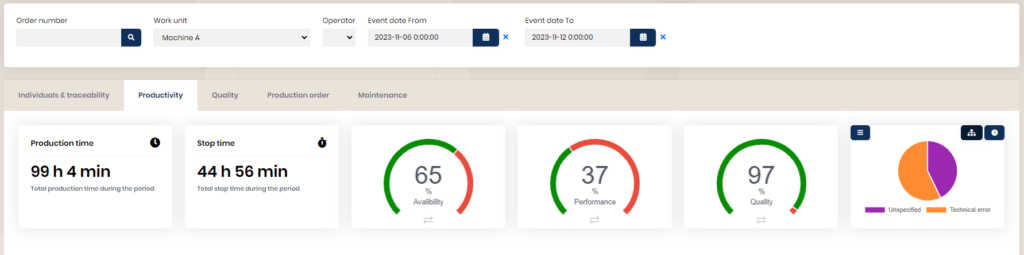

- Visualization of Availability, Performance, and Quality: OEE values for availability, performance, and quality are graphically presented, providing a comprehensive view of equipment and process efficiency.

- Stops Visualization: Stops are displayed as portions for each case or category, allowing for a detailed understanding of the reasons behind interruptions and downtimes.

- Operations and Stops Listing: A detailed list of operations and stops is available, facilitating a closer examination of specific events. Additionally, this information can be conveniently exported to Excel for further analysis and reporting.

OEE can be delivered as part of a larger LE.MES solution or as a separate OEE-packaging.